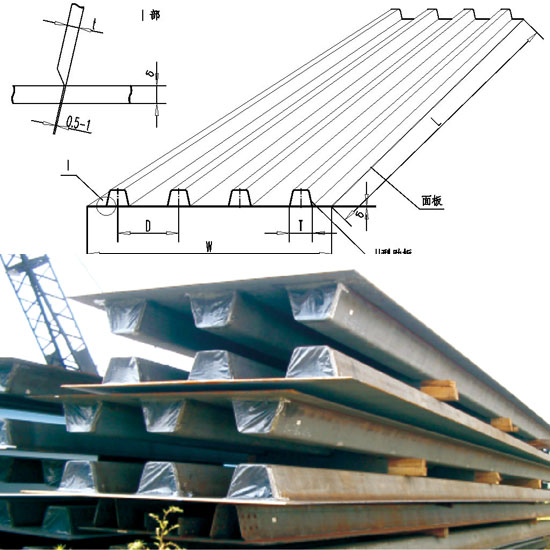

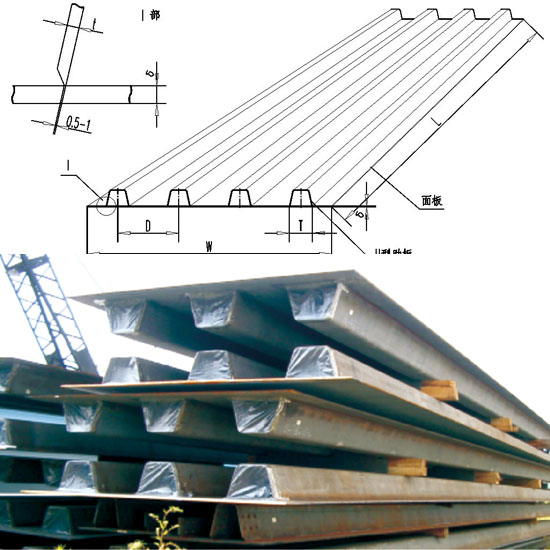

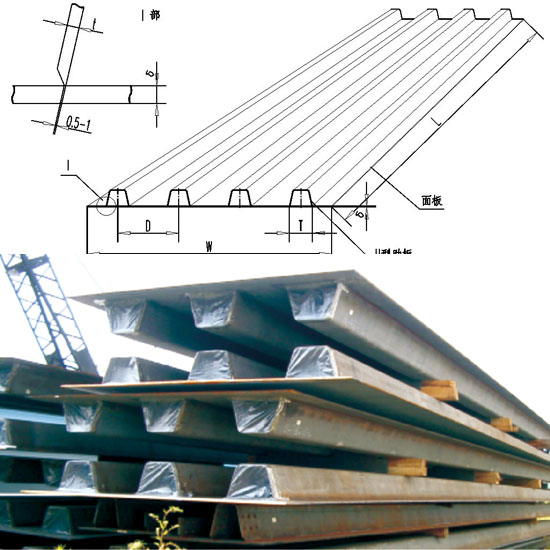

With the increasingly development of big steel structure bridge project, importance on automatic manufacturing of U-rib is growing day by day because of the large demand and high requirements about productivity and welding quality. Our company provides various bridge face manufacturing equipments for SHAN HAI GUAN Bridge Manufacturing Factory, WUHAN Shipping Heavy-duty Industry Company, Shanghai ZMPC and other bridge steel structure manufacturers in China. We have gained favorable comments. Structure of bridge face U-rib is as below:

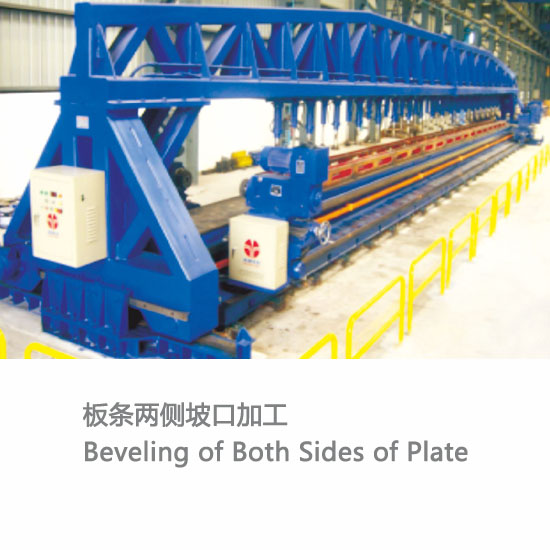

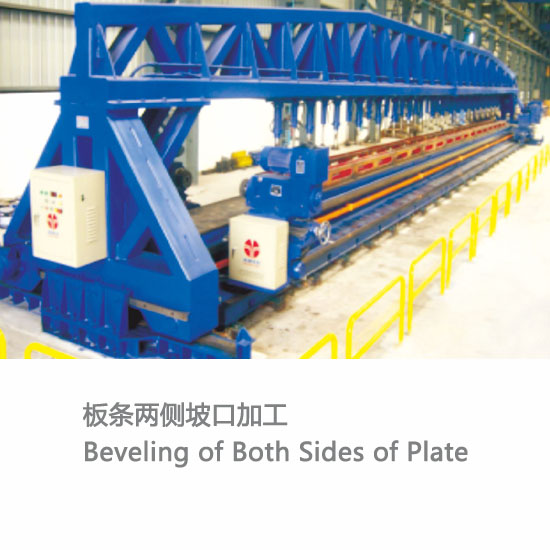

Both sides beveling are realized by dual-side or tri-side synchronous edge milling machine which can be customized according to the customer's requirements about material thickness, width and length. Ten pieces of plate can be machined together in stacking manner with great efficiency.

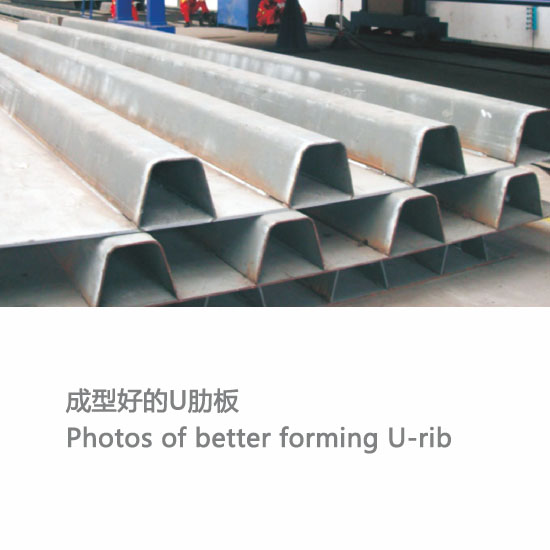

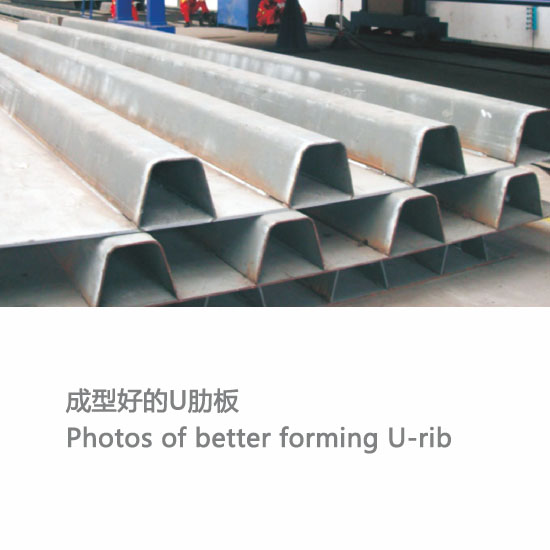

U-rib forming can be done by molding machine or press brake machine. Molding machine can form the required shapes and plane the bevel and shunt edge. It has high productivity; while it needs large investment and it is very easy to cause deflects of wavy edge, uneven bevel and irregular forming. Another method: after plate plasma cutting, machining bevels first, and then form the required shape by CNC press brake machine. Comparatively, it needs less investment and has a better regular forming.

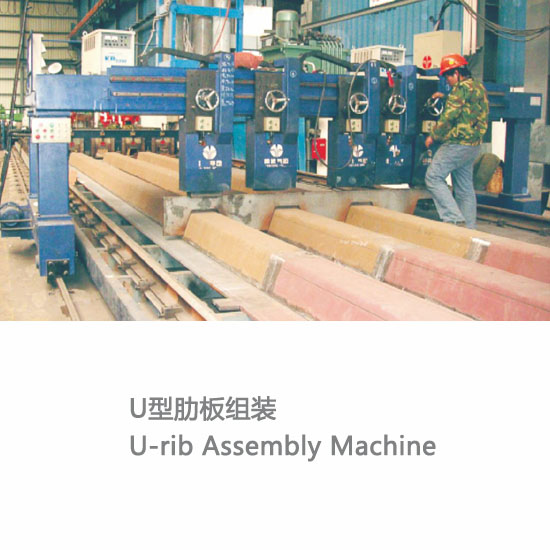

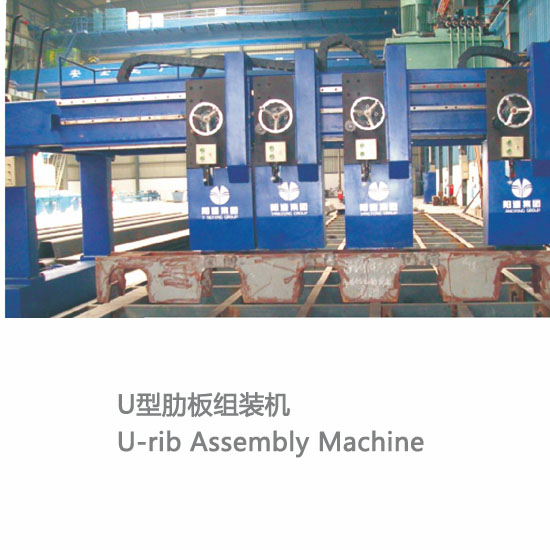

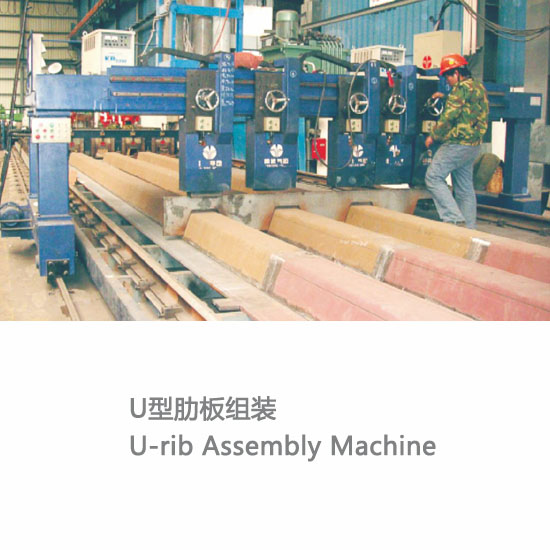

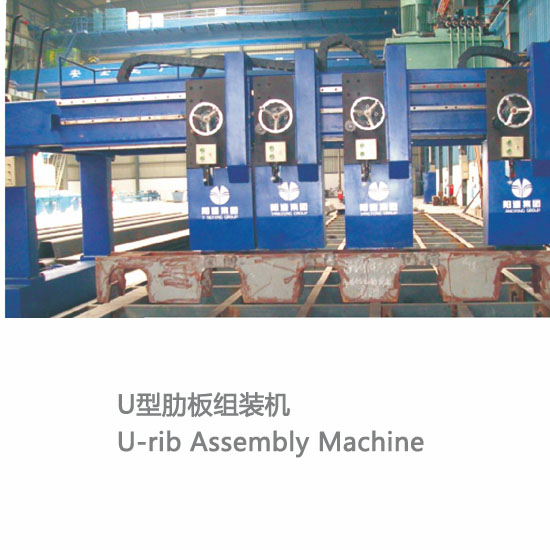

The panel will be placed on the worktable and positioned against the positioning unit of the worktable tightly. The U-rib will be positioned, pressed and tack-welded according to the pre-marked line on the panel section by section. There are two types of pressing: hydraulic type and hand screw type.

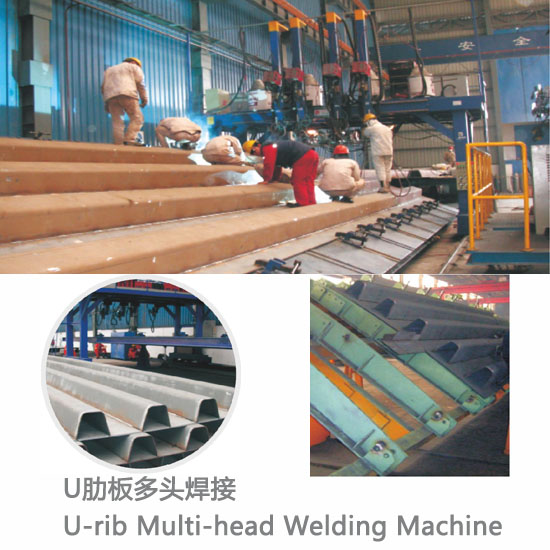

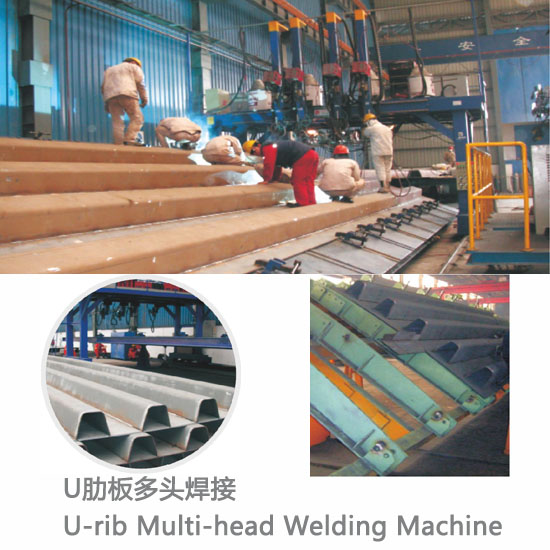

After U-rib assembly, fixed on the welding platform which can tilt to some angle. Welding torch can follow the seam reliably by means of mechanical tracking device. Gantry traveling adopts VFD (variable frequency drive) speed adjustment. It welds both sides of U-rib on the panel synchronously. Welding technology can be MIG or SAW. Welding platform can be designed as anti-deformation bed-jig or flat worktable.

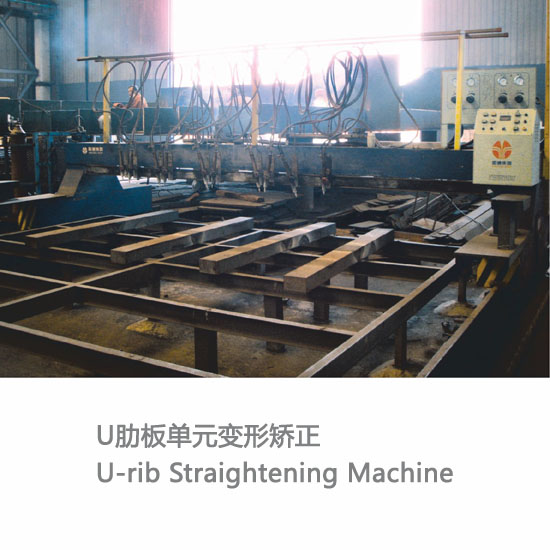

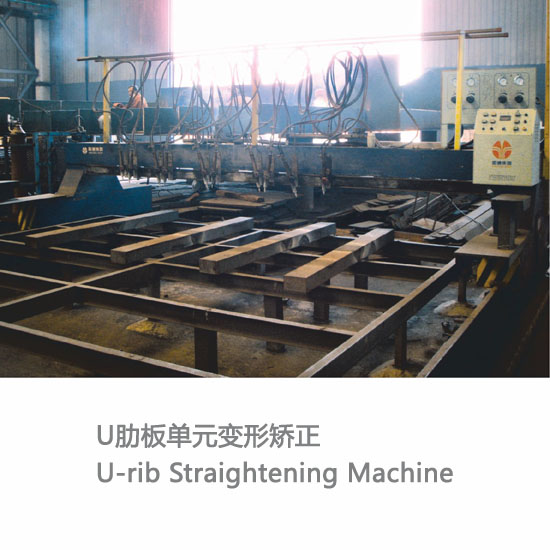

After welding, U-rib panel will be distorted inevitably due to heat input. Overturning 180 degree after welding to do the flame straightening.